All issues

Volume 80, Issue 3

Displaying 1-9 of 9 articles from this issue

- |<

- <

- 1

- >

- >|

Regular Article

-

Yutaka Midorikawa, Masaaki Nakai, Kaoru Midorikawa, Mitsuo Niinomi2016 Volume 80 Issue 3 Pages 165-170

Published: 2016

Released on J-STAGE: February 25, 2016

Advance online publication: January 15, 2016JOURNAL FREE ACCESSA novel method for detecting antimicrobial activity using an innate property of the Salmonella bacteria, namely, the ability of Salmonella to produce hydrogen sulfide (H2S) was developed in this study. The effectiveness of the method was evaluated by comparing the antibacterial activity of copper to that of aluminum. Salmonella was inoculated over the entire surface of deoxycholate hydrogen sulfide lactose (DHL) agar plates that included Ammonium ferric citrate (C6H8FeN). Approximately 25 μL of cupric chloride (CuCl2, 1% weight ratio) solution or aluminum chloride (AlCl3, 1% weight ratio) solution was added to the center of the medium. The surface of the medium was covered with plastic PET (polyethylene terephthalate) material to induce an anaerobic state. Salmonella was cultured under anaerobic conditions at 310 K (37℃) for 86.4 ks (24 h). The antibacterial activity of copper was determined by observing the medium surface color change due to iron sulfide (FeS) formation, which was caused by the production of H2S by Salmonella; blackness indicated presence of newly formed FeS. A quantitative evaluation of copper's antimicrobial activity was performed using a gradient of CuCl2 concentrations; results were compared with those of the present standard method, Kirby-Bauer disk diffusion method on the Mueller Hinton medium. Finally, in order to evaluate the antibacterial activity of metals, Salmonella was inoculated on DHL agar plates. Subsequently, Japanese coins (1 yen, 5 yen, 10 yen, 50 yen, 100 yen and 500 yen coins) were placed on the agar and cultured at 310 K for 86 ks. Salmonella cultured in the presence of AlCl3 produces black color, while no blackening is observed with CuCl2, suggesting that copper possesses an antibacterial property against Salmonella. CuCl2 suppresses H2S production by Salmonella, as Cu2+ forms a transparent circle or ellipse (new halo) around the point at which CuCl2 had has been plated. The size of the new halo increases in direct proportion to the concentration of CuCl2. The halo is no longer visible at 0.034 mg of CuCl2 in our method, while the halo disappears with 4.34 mg of CuCl2 in the Kirby-Bauer method. Therefore, the present method is 129 times more sensitive than the standard method, suggesting increased usefulness and effectiveness in testing antibacterial activity. No FeS-dependent black circle is formed under any of the coins, with the exception of the 1-yen coin, which contains aluminum and no copper. Therefore, the copper-containing coins have an antibacterial effect.

View full abstractDownload PDF (1942K) -

Yukiko Ogawa, Daisuke Ando, Yuji Sutou, Junichi Koike2016 Volume 80 Issue 3 Pages 171-175

Published: 2016

Released on J-STAGE: February 25, 2016

Advance online publication: January 15, 2016JOURNAL FREE ACCESSMg-20.5 at% Sc alloy with hcp (α)+bcc (β) two-phase alloy was investigated to understand the effects of aging treatment at 200℃ on microstructure, hardness and tensile properties. The Mg-Sc alloy ingot was prepared by induction melting in Ar atmosphere, and then hot rolled at 600℃ followed by cold rolling into a sheet. The rolled specimens were annealed at 600℃ to obtain α+β two-phase microstructure. Then, the annealed specimens were aged at 200℃ for various time. Vickers hardness of the α+β two-phase alloy drastically increased after a certain incubation time and then reached maximum hardness of 142.8 Hv. The incubation time of the Mg-20.5 at% Sc alloy with the α+β two-phase was longer than that of the same alloy with a β single-phase. Ultimate tensile strength (UTS) and elongation of the as-annealed specimen were 280 MPa and 28.2%, respectively. Meanwhile, the specimen aged at 200℃ for 14.4 ks showed a UTS of 357 MPa and an elongation of over 12%. The specimen aged for 18 ks showed a higher UTS of 465 MPa while keeping a better elongation of 6.9%. It was found that the age hardening of the Mg-Sc alloys were attributed to the precipitation of very fine α phase in β phase.

View full abstractDownload PDF (1897K) -

Weiwei Zheng, Tetsuo Shoji, Haruki Itofuji, Jianhua Zhang2016 Volume 80 Issue 3 Pages 176-185

Published: 2016

Released on J-STAGE: February 25, 2016

Advance online publication: January 15, 2016JOURNAL FREE ACCESSThe purpose of this study is to analyze the microstructure and chemical composition of the oldest heavy section cast iron cannon in China, which was manufactured at the early Ming dynasty in the year of 1377 with the inscription of Hongwu. It is worthwhile to study any characteristic casting processes and advancement of the heavy section casting technology during the Ming dynasty because the cannon technology could be developed based upon the leading technology of that age. This cannon has been preserved and displayed at Shanxi Province Art Museum. Some microstructural analysis was performed on site by use of portable grinding and polishing tools for the metallurgical examination. In addition, more detailed metallurgical examination by EDX, XPS, high temperature optical microscope (OM) and DSC analysis was performed on a small sample taken from the cannon. Chemical analysis was also performed on the grinding chips and powder collected during the metallurgical surface preparation. A thermodynamic phase diagram was calculated by CALPHAD method for the material with the same chemical composition as measured. After the detailed metallurgical examination and chemical composition analysis, it turned out that the cannon has a chemical composition range of minor elements as: C: 1.36-1.8 mass%, S: 0.58-0.78 mass%, P: 0.61-0.81 mass%, Si: 0.45-0.61 mass%, and shows a uniform hypereutectoid microstructure. Taking into account the evidence of no microstructural gradient from a surface to inside which is not common in ancient decarburized cast iron, the cannon is highly likely to be made by a cast steel rather than by a cast iron.

Non-metallic inclusions are observed both by OM and by a scanning electron microscope (SEM) on the sample. A high temperature optical microscope with an in-situ heating capability was used to directly observe any phases with a lower melting temperature. Also DSC analysis was performed on the sample to examine any phase change at some specific temperature. Based upon these observations and analysis, it was concluded that the Hongwu cannon was made by cast steel with a hypereutectoid microstructure. This microstructure contained a eutectic phase in pro-eutectoid cementite, which suggests a formation of steadite Fe-Fe3C-Fe3P with a low melting temperature of 1227 K. This finding strongly suggests that, instead of cast iron technology, cast steel technology had already existed and was put in use for heavy-section cannon production during early Ming Dynasty in China.

View full abstractDownload PDF (13407K) -

Reisho Onodera, Kazuki Ohtake, Kohki Takahashi, Shojiro Kimura, Kazuo ...2016 Volume 80 Issue 3 Pages 186-191

Published: 2016

Released on J-STAGE: February 25, 2016

Advance online publication: January 15, 2016JOURNAL FREE ACCESSA vibrating sample magnetometer for measurements at high magnetic fields and high temperatures (HT-VSM) was developed. The first-order antiferro-ferromagnetic phase (AFM-FM) transition in B2 FeRh alloy was investigated using the HT-VSM in a wide range of temperatures and magnetic field regions. At 300 K, we succeeded in observing a field-induced AFM-FM transition by magnetization measurements up to 19 T. The transition field decreases with increasing sample temperature.

View full abstractDownload PDF (2794K) -

Masaru Kamiya, Hisao Kikugawa, Takashi Asaka, Masae Kanda, Yoshitake N ...2016 Volume 80 Issue 3 Pages 192-196

Published: 2016

Released on J-STAGE: February 25, 2016

JOURNAL FREE ACCESSUltra-high molecular weight polyethylene (UHMWPE) has been used for the bearing materials of total joint prostheses. Strength criterion of medical UHMWPE is the tensile properties. However, the compression characteristic which is important in the contact surfaces of the prosthesis has not been considered. In this study, we examined the effect of gamma and electron beam irradiation treatment on compressive properties of medical UHMWPE. The compressive properties (Young's modulus and proof stress) by γ irradiation was higher than the specimens of unirradiated. The plastic flow pressure by electron beam irradiation showed higher than the specimens of unirradiated. Inhibition of plastic deformation of the non-crystalline structure part by electron beam irradiation is considered to have caused the increase in the plastic flow pressure. Electron beam irradiation treatment was found to be effective for the surface enhancements of the medical UHMWPE. ESR signal was clearly observed in the irradiated UHMWPE. From these results, it was found that there was a high possibility that dangling bonds were formed in the irradiated UHMWPE.

View full abstractDownload PDF (1812K) -

Shuhei Shinzato, Masato Wakeda, Shigenobu Ogata2016 Volume 80 Issue 3 Pages 197-205

Shuhei Shinzato, Masato Wakeda, Shigenobu Ogata2016 Volume 80 Issue 3 Pages 197-205

Published: 2016

Released on J-STAGE: February 25, 2016

Advance online publication: January 22, 2016JOURNAL FREE ACCESSIt is well known that the mechanical strength of iron is significantly changed by alloying. However, atomistic origin and underlying mechanism are still unclear. Since the strength change with respect to solute concentration is very sensitive and highly non-linear, the way of empirical prediction may contribute little to designing the mechanical strength by alloying. In this study, we theoretically construct a model which predicts temperature, strain rate, and solute concentration dependencies on critical resolved shear stress (CRSS) and yield stress of BCC iron alloys with dilute substitutional solutes based on atomistic analysis of the dislocation-solute atom interaction. In the coarse-grained BCC polycrystalline metals, the mechanical strength and deformation are dominated by screw dislocation motion consisting of kink nucleation and migration processes. Thus, our model is based on atomistically computed activation free energies for kink nucleation and migration of screw dislocation. We eventually apply our model to Fe-Si dilute alloy system as a representative example of BCC dilute alloys, and the theoretically predicted CRSS by our model is compared with an experimental one.

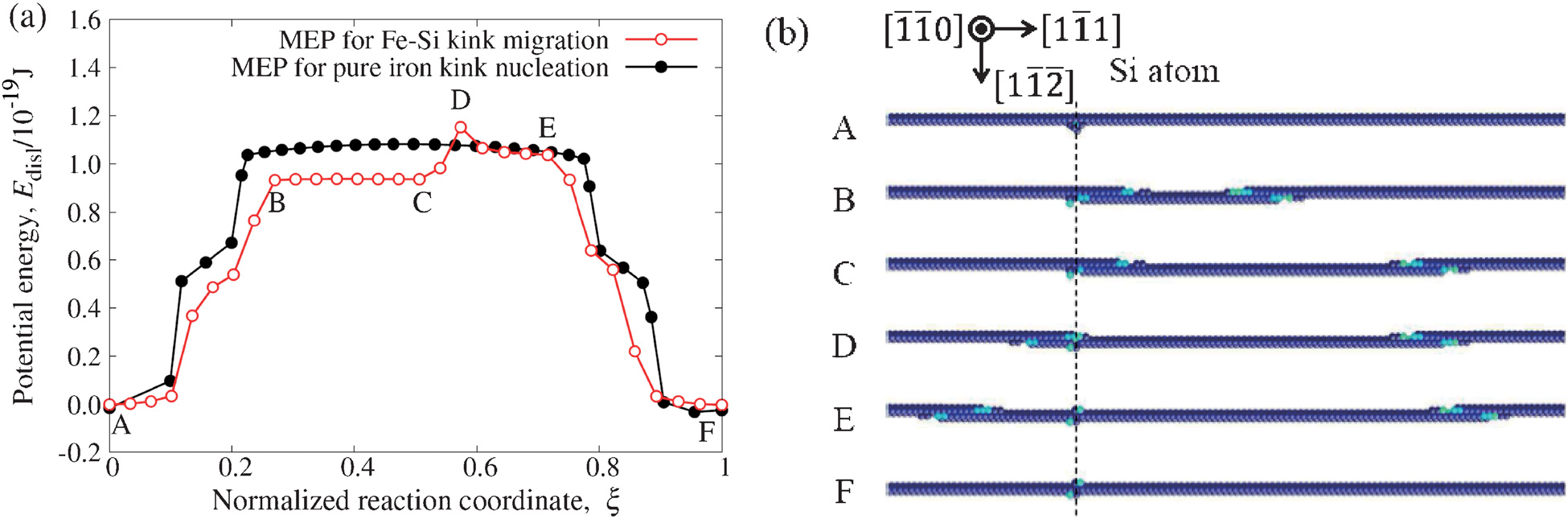

Fig. 6 Fullsize ImageAnalysis result of kink migration process. (a) Change in potential energy during screw dislocation glide, in which kink interact with Si atom in the migration process, obtained by NEB analysis. MEP for kink nucleation process of pure iron was obtained by the work of Wakeda et al.12) (b) Atomistic structure of dislocation line during kink migration through Si atom.View full abstractEditor's pick

Fig. 6 Fullsize ImageAnalysis result of kink migration process. (a) Change in potential energy during screw dislocation glide, in which kink interact with Si atom in the migration process, obtained by NEB analysis. MEP for kink nucleation process of pure iron was obtained by the work of Wakeda et al.12) (b) Atomistic structure of dislocation line during kink migration through Si atom.View full abstractEditor's pickBest Paper Award 2017

Download PDF (4643K) -

Masaaki Tsukamoto2016 Volume 80 Issue 3 Pages 206-212

Published: 2016

Released on J-STAGE: February 25, 2016

Advance online publication: January 29, 2016JOURNAL FREE ACCESSDiffusion bonding method of chromium-copper alloy having a stable oxide layer was developed to improve tensile strength with low deformation of a specimen. In a manner of breaking the oxide layer by means of pressing, the tensile strengths were not well obtained and the specimens were moreover deformed. As the reason, contained chromiums were moved onto the bonding surfaces from bulk and subsequent oxidized with heating even in vacuum. It could be suppressed when the roughness of bonding surfaces was significantly smoothed. The specimens with smoothing surfaces were diffusion-bonded at 1073~1173 K for 3.6 ks without pressing. All the bonded specimens were fractured at the base metal. The bonded interface in the specimen fabricated at 1173 K could not specified on the SEM image. Also, the diffusion bonding was carried out with inserting a nickel film between the bonding surfaces in order to identify mutual diffusion. Nickel was theoretically diffused into chromium-copper alloys. It proved that metallic bonds were achieved between the bonded surfaces. However, a chromium oxide layer are easy to be generated at room temperature in atmosphere. The oxide layers had been already formed around chromium precipitations existing on the bonding surfaces before diffusion bonding. It was found that these cohered with heating, which enable the specimens to increase the bonded area. On the other hand, grain boundary migration over the bonded interface was not partly occurred in the specimen fabricated at 1073 K. An oxide and a void have been known to prevent the migration. In the case of diffusion bonding at 1173 K, the bonded interface disappeared by the migration in spite of residual oxide aggregations. Therefore, the void would be responsible for delaying the migration.

View full abstractDownload PDF (13223K) -

Kenta Arai, Katsuhisa Nagayama2016 Volume 80 Issue 3 Pages 213-216

Published: 2016

Released on J-STAGE: February 25, 2016

Advance online publication: January 22, 2016JOURNAL FREE ACCESSWe have reported the formation of InSb particles using a short-drop tube process. Most InSb particles produced by in this manner indicated polycrystalline structure, and the condition for the formation of single crystalline particles has not been clear. In this study, we focused on the difference in the melt temperature condition and solidification process of each particle, and aimed to examine the factor controlling formation of single crystalline InSb particles. We have investigated the relationship between melt temperature, solidification time, and surface structure of InSb particles and aimed to improve the frequency of formation of single crystalline particles. Consequently, we concluded that slow crystal growth from low temperature is effective for the formation of single crystalline particles of InSb. The rate of smooth surface particles that indicated single crystalline structure was improved in InSb particles produced in He atmosphere at a pressure of 0.5 atm from above the melting point of the InSb compound phase compared with those formed by the conventional method.

View full abstractDownload PDF (1691K) -

Isao Matsui, Naoki Omura, Mingjun Li, Yuichiro Murakami, Shuji Tada2016 Volume 80 Issue 3 Pages 217-223

Published: 2016

Released on J-STAGE: February 25, 2016

Advance online publication: January 22, 2016JOURNAL FREE ACCESSA substitute for propionic acid, which is a complexing agent in the Ni-W electrodeposition process for producing bulk nanocrystalline alloys with high ductility, was explored. Bulk nanocrystalline Ni-W alloys were electrodeposited using electrolyte that primarily consisted of nickel sulfamate and sodium tungstate with sodium propionate and/or sodium gluconate. Their W content, impurity contents, microstructure, and mechanical properties were investigated. The Ni-W alloys electrodeposited from conventional bath exhibited tensile strength of 1.66 GPa and elongation of 6.5%. Substitution of propionic acid by sodium propionate enhanced tensile elongation up to 11.3% along with high strength of 1.65 GPa. Also, substitution by sodium gluconate enhanced tensile strength up to 1.80 GPa with elongation of 5.2%. The results of this study demonstrate that the propionic acid in the Ni-W electrodeposition process can be replaced by sodium propionate without property degradation.

View full abstractDownload PDF (3280K)

- |<

- <

- 1

- >

- >|