- |<

- <

- 1

- >

- >|

-

Kaishi Sudo, Daisuke Matsunaka, Hidetoshi SomekawaArticle type: Regular Article

2021 Volume 85 Issue 1 Pages 1-6

Published: January 01, 2021

Released on J-STAGE: December 25, 2020

Advance online publication: December 14, 2020JOURNAL FREE ACCESS FULL-TEXT HTMLEffects of a grain boundary (GB) on local mechanical properties in magnesium were investigated by nanoindentation. Based on the evaluated activation volume values, it was found that pop-in phenomena in matrix and near GB could be attributed to equivalent defect events. The pop-in load and hardness were higher for indentation near GB than in matrix, due to dislocation-GB interaction. Formation of {1012} deformation twins was observed in the vicinity of the indents. The twin growth was found to be suppressed near GB.

View full abstractDownload PDF (4405K) Full view HTML

View full abstractDownload PDF (4405K) Full view HTML -

Takuya Hashimoto, Ken-ichi Ikeda, Seiji MiuraArticle type: Regular Article

2021 Volume 85 Issue 1 Pages 7-16

Published: January 01, 2021

Released on J-STAGE: December 25, 2020

Advance online publication: December 14, 2020JOURNAL FREE ACCESS FULL-TEXT HTMLNanoindentation tests were conducted near the grain boundary (GB) of the Al-Mg-Si alloy, and the influence of GB character on the aging precipitation behavior and the mechanical properties was confirmed. After obtaining the GB characters by electron back scattered diffraction (EBSD) analysis and nanoindentation tests were carried out on under-aged, peak-aged, and over-aged samples. And then, the indentation areas were observed by back scattered electrons imaging (BSE) in order to identify indentation positions to the GB. In this study, for the GB character, focusing on the rotation angle, the high-angle GB (HAGB) and the low-angle GB (LAGB) were selected. In addition, coincidence site lattice GBs (CSL) were selected as the special GB. In the 180℃ under-aged sample, the nano-hardness near GB is higher than that far from GB, while 180℃ peak-aged and 250℃ aged samples, the nano-hardness is lower than that far from GB. Then the amount of change in hardness of HAGB was larger than that of the LAGB. This suggests that the GB character affects the aging precipitation behavior and mechanical properties.

Fig. 3 Nano-hardness around grain boundaries at aging temperature of 180℃; (a) at under-aged around HAGB, (b) at peak-aged around HAGB, (c) at under-aged around LAGB, (d) at peak-aged around LAGB, (e) at under-aged around CSL3, (f) at peak-aged around CSL3, (g) at under-aged around CSL5 and (h) at peak-aged around CSL5. Fullsize ImageView full abstractDownload PDF (6270K) Full view HTML

Fig. 3 Nano-hardness around grain boundaries at aging temperature of 180℃; (a) at under-aged around HAGB, (b) at peak-aged around HAGB, (c) at under-aged around LAGB, (d) at peak-aged around LAGB, (e) at under-aged around CSL3, (f) at peak-aged around CSL3, (g) at under-aged around CSL5 and (h) at peak-aged around CSL5. Fullsize ImageView full abstractDownload PDF (6270K) Full view HTML -

Motomichi Koyama, Keiichiro Nakafuji, Kaneaki TsuzakiArticle type: Regular Article

2021 Volume 85 Issue 1 Pages 17-22

Published: January 01, 2021

Released on J-STAGE: December 25, 2020

Advance online publication: December 14, 2020JOURNAL FREE ACCESS FULL-TEXT HTMLToward establishing in-situ electron channeling contrast imaging (ECCI), we present three insights in ECC images, which are related to {111} surface traces in face-centered cubic alloys. For this purpose, ECCI was carried out under tensile loading in an austenitic steel. First, dislocation slip and stacking fault formation during deformation can be distinguished in ECCIs. Second, crystallographic orientation can be determined by three {111} traces in ECCIs. Third, shrinkage of stacking faults on {111} planes under unloading was observed by in-situ ECCI even in a smooth specimen, which implies a significant difference between in-situ and ex-situ observations.

Fig. 6(a)-(c) Magnifications of Fig. 5(b). The arrows indicate the specimen surface side of the stacking faults. (b′), (c′) Schematics for the contrast gradient of the stacking faults. Fullsize ImageView full abstractDownload PDF (6029K) Full view HTML

Fig. 6(a)-(c) Magnifications of Fig. 5(b). The arrows indicate the specimen surface side of the stacking faults. (b′), (c′) Schematics for the contrast gradient of the stacking faults. Fullsize ImageView full abstractDownload PDF (6029K) Full view HTML -

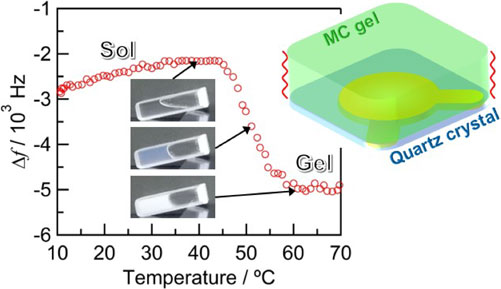

Kenji Yamaoka, Yoshihisa Fujii, Naoya TorikaiArticle type: Regular Article

2021 Volume 85 Issue 1 Pages 23-29

Published: January 01, 2021

Released on J-STAGE: December 25, 2020

Advance online publication: December 18, 2020JOURNAL FREE ACCESS FULL-TEXT HTMLThe gelation behavior of aqueous methylcellulose (MC) solution was evaluated by using quartz crystal microbalance (QCM) which is an extremely sensitive mass balance that measures nano-gram to micro-gram level changes in mass per unit area. Then, possibility of QCM for interfacial selective viscoelasticity measurement was investigated. The viscosity changes accompanying with gelation were observed as the resonance frequency shift. The gelation temperature determined from the temperature dependence of the resonance frequency shift showed good agreement with the value obtained by visual observation and rheology measurement. Furthermore, MC molecules were adsorbed, and the concentration was increased at interface with hydrophobic quartz units due to the interfacial state. It was suggested that QCM enables to evaluate the interfacial viscoelasticity.

View full abstractDownload PDF (4486K) Full view HTML

View full abstractDownload PDF (4486K) Full view HTML -

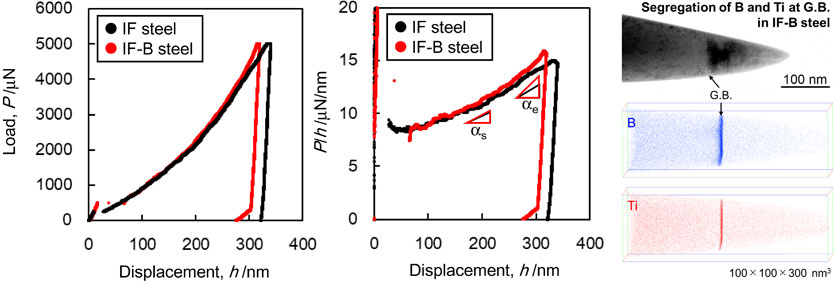

Kazuki Endoh, Seiichiro Ii, Yuuji Kimura, Taisuke Sasaki, Sota Goto, T ...Article type: Regular Article

2021 Volume 85 Issue 1 Pages 30-39

Published: January 01, 2021

Released on J-STAGE: December 25, 2020

JOURNAL FREE ACCESS FULL-TEXT HTMLNanoindentation measurements on various grain boundaries were performed to clarify the effects of the geometry of neighboring grains and the addition of boron (B) on plasticity resistance in the vicinity of grain boundaries in interstitial free (IF) steels. We define a parameter, α, which is measured by the slope of a P/h - h curve with load, P, and displacement, h, to estimate the resistance against plastic deformation in the grain interior and at the grain boundaries. The value of α is almost constant with the geometric compatibility factor of the grain boundaries. This result shows that the geometry of the neighboring grains does not affect the plasticity resistance at the grain boundaries. However, the value of α increases by the addition of B due to the segregation of B and Ti to the grain boundaries. It is indicated that the elemental segregation to the grain boundaries enhances the resistance to the plastic deformation in the vicinity of the grain boundaries.

View full abstractDownload PDF (4845K) Full view HTML

View full abstractDownload PDF (4845K) Full view HTML -

Katsuya Nakano, Kengo Takeda, Seiichiro Ii, Takahito OhmuraArticle type: Regular Article

Katsuya Nakano, Kengo Takeda, Seiichiro Ii, Takahito OhmuraArticle type: Regular Article

2021 Volume 85 Issue 1 Pages 40-48

Published: January 01, 2021

Released on J-STAGE: December 25, 2020

Advance online publication: December 18, 2020JOURNAL FREE ACCESS FULL-TEXT HTMLA plasticity resistance by a grain boundary was evaluated by nanoindentation measurement in the vicinity of the grain boundary for austenitic stainless steels. Converting a load (P) - displacement (h) relation to a P/h - h curve, the plasticity resistance can be evaluated in the parameter α with hardness dimension obtained as the slope on the loading curve. The slope α is constant until the plastic zone underneath the indenter reaches to the grain boundary at a certain penetration depth (stage I), and then turns into a higher value in the deeper penetration depth range (stage II). The lower α in the stage I (αI) means the deformation resistance in the grain interior, and that in the stage II (αII) includes the deformation resistances of both the grain interior and the grain boundary. Therefore, Δα = αII − αI could correspond to the plasticity resistance by the grain boundary. It has been found that the average of Δα is higher for the nitrogen-added sample than that for the nitrogen-free one, suggesting a nitrogen effect including segregation on the plasticity resistance by a grain boundary.

Fig. 4 (a) Typical load (P)-displacement (h) curves for grain interior and near grain boundary and (b) P/h-h curves for grain interior and near grain boundary. Fullsize ImageView full abstractEditor's pick

Fig. 4 (a) Typical load (P)-displacement (h) curves for grain interior and near grain boundary and (b) P/h-h curves for grain interior and near grain boundary. Fullsize ImageView full abstractEditor's pickBest Paper Award 2022

Download PDF (3484K) Full view HTML

- |<

- <

- 1

- >

- >|