- |<

- <

- 1

- >

- >|

-

Jundai Goto, Toshiyuki Koyama, Yuhki TsukadaArticle type: Regular Article

2021 Volume 85 Issue 3 Pages 89-94

Published: March 01, 2021

Released on J-STAGE: February 25, 2021

JOURNAL FREE ACCESS FULL-TEXT HTMLThe anomalous discontinuous precipitation which is called “Cellular Decomposition (CD)” has been observed in Cu-Ni-X (X = Co,Fe) ternary systems, i.e., the precipitate morphology in cell region is a nanoscale fine fiber, the direction of the fibers does not take specific crystal orientation, and the morphology is wavy. In this study, we elucidated the reason why such an unusual cellular decomposition occurs by means of the Calphad method and phase-field simulations. In particular, we focused on the spinodal decomposition inside the grain before CD. The results showed that the Ni component preferentially segregates at the interface region between precipitate and matrix phase in the two-phase microstructure by spinodal decomposition, and the Ostwald ripening is suppressed due to the low solute solubility of the matrix phase in the Cu-Ni-X (X = Co,Fe) system. Hence, the spinodal microstructure formed inside the grain before CD is trapped into high-energy level, which induces the discontinuous precipitation with high speed grain boundary migration, that provides “Cellular Decomposition”.

Fig. 2 Two-dimensional simulation result of spinodal decomposition in Cu-25.6 at%Ni-16.4 at%Co alloy at 773 K for t = 10 [(a), (c)] and t = 140 [(b), (d)]. The local composition is indicated by RGB color combination in (a) and (c). The composition of Ni component is represented by gray scale contrast in (b) and (c). Fullsize ImageView full abstractDownload PDF (2158K) Full view HTML

Fig. 2 Two-dimensional simulation result of spinodal decomposition in Cu-25.6 at%Ni-16.4 at%Co alloy at 773 K for t = 10 [(a), (c)] and t = 140 [(b), (d)]. The local composition is indicated by RGB color combination in (a) and (c). The composition of Ni component is represented by gray scale contrast in (b) and (c). Fullsize ImageView full abstractDownload PDF (2158K) Full view HTML -

Kodai Imamura, Akio NishimotoArticle type: Regular Article

2021 Volume 85 Issue 3 Pages 95-102

Published: March 01, 2021

Released on J-STAGE: February 25, 2021

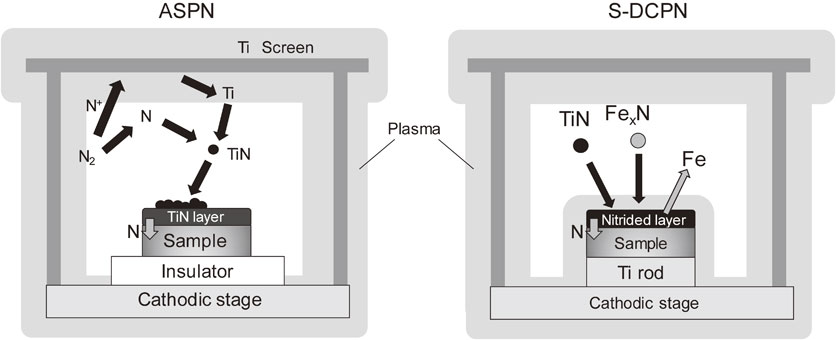

Advance online publication: January 22, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLIn order to investigate the effect of the screen hole state of the active screen plasma nitriding (ASPN) process using Ti screen, low carbon steel S15C was treated by ASPN treatment and DC plasma nitriding treatment (S-DCPN) using the Ti screen with the hole diameter of ϕ5 mm, 10 mm, and 20 mm and the open area ratio of 0%, 15%, 35%, and 55%. Plasma nitriding was performed at 873 K for 180 min at a gas pressure of 300 Pa under an atmosphere of 75% N2 + 25% H2. After the nitriding treatment, X-ray diffraction (XRD), surface microstructure observation, cross-section microstructure observation, wear test, Vickers hardness test, glow discharge optical emission spectrometry (GD-OES), and corrosion test were performed. As a result, the wear resistance of the ASPN-treated samples was improved under the condition that the deposit particles were small and the deposit layer was thick. In the cross-sectional microstructure of the S-DCPN-treated samples, a compound layer composed of iron nitrides and a diffusion layer in which γ’-Fe4N was precipitated by nitrogen diffusion were confirmed. The surface compound layer of iron nitrides was not formed when a screen with a hole size of 20 mm and open area ratio of 55% was used. The results of SEM-EDX also confirmed the diffusion of titanium by S-DCPN treatment using a Ti screen.

Fig. 1 Schematic illustration of plasma nitriding setups: ASPN and S-DCPN. Fullsize ImageView full abstractDownload PDF (4680K) Full view HTML

Fig. 1 Schematic illustration of plasma nitriding setups: ASPN and S-DCPN. Fullsize ImageView full abstractDownload PDF (4680K) Full view HTML -

Jun Kubo, Yuichiro Koizumi, Takuya Ishimoto, Takayoshi NakanoArticle type: Regular Article

2021 Volume 85 Issue 3 Pages 103-109

Published: March 01, 2021

Released on J-STAGE: February 25, 2021

Advance online publication: January 18, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLMetal additive manufacturing (AM) technologies are attracting attentions not only as a forming process but also as microstructure controlling processes. In powder bed fusion (PBF) AM, crystal orientations can be controlled by scanning strategies of energy beam. To optimize microstructures, computer simulations for predicting microstructures play very important roles. In this work, we have developed simulation programs to explain the mechanism of the crystal orientation control. First, we simulated the shape of melt pool by analyzing the heat transfer using apparent heat conductivity when the penetration of laser beam through keyholes was taken into consideration because of the evaporation and accompanying convections. It was assumed that the primary crystal growth direction can be determined by the temperature gradient, and the crystals grow keeping the growth direction as generally recognized. The shapes of simulated melt pools agree well with experimental observations. The modified cellular automaton simulations successfully reproduced two typical textures with different preferential orientations along the building directions of 〈001〉 and 〈011〉 when the bidirectional scanning with and without a rotation of 90° was accomplished between the layers.

Fig. 8 Comparison of analysis results (lower side) with experimental results (upper side: after Ishimoto et al.1)) of scan strategy X. Fullsize ImageView full abstractDownload PDF (6250K) Full view HTML

Fig. 8 Comparison of analysis results (lower side) with experimental results (upper side: after Ishimoto et al.1)) of scan strategy X. Fullsize ImageView full abstractDownload PDF (6250K) Full view HTML -

Jun-ichi Saito, Yohei Kobayashi, Hideo ShibutaniArticle type: Regular Article

2021 Volume 85 Issue 3 Pages 110-119

Published: March 01, 2021

Released on J-STAGE: February 25, 2021

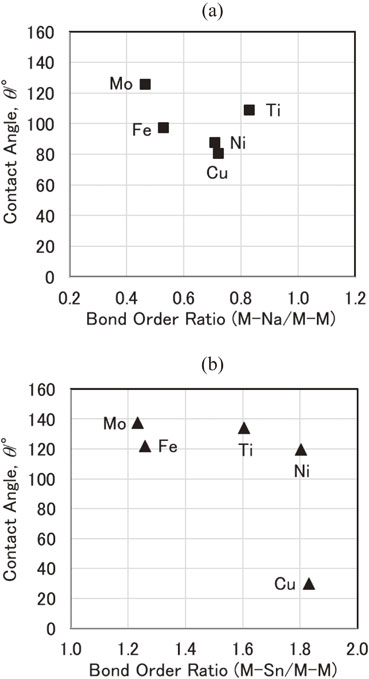

Advance online publication: February 05, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLWettability of pure transition metals with liquid sodium or liquid tin has been evaluated using a contact angle droplet method. Titanium, iron, nickel, copper and molybdenum pure metals were selected as specimens in this experiment. All experiments were carried out in high purity argon gas and extremely low moisture to avoid influence of oxygen to liquid metal. Measurement temperature was set just above the melting temperature of each liquid metal. As a result, for both liquid sodium and liquid tin, the measured contact angle changed depending on the atomic number of substrate metals. An electronic structure of the interface between liquid metal and substrate metal was calculated by the molecular orbital method. Simple cluster models of the interface between liquid metal and substrate transition metals were used in this calculation. It was found that the calculation results well express an electronic state of interface. The atomic bonding between liquid metal atom and substrate metal atom changed depending on the kind of substrate metal. Also, the atomic bonding between substrate metal atoms changed similarly. It became clear that there was a reasonable relationship between an atomic bonding ratio and the contact angle. It clearly suggested the atomic bonding affected wettability between liquid metal and substrate metal. The atomic bonding was obtained as one of indications to reveal the wettability by transition metals with liquid metals.

Fig. 16 Relationship between contact angle and bond order Ratio (Centered M-LM / Centered M-1st. Neighbor M) of (a) liquid sodium and (b) liquid tin. Fullsize ImageView full abstractDownload PDF (6861K) Full view HTML

Fig. 16 Relationship between contact angle and bond order Ratio (Centered M-LM / Centered M-1st. Neighbor M) of (a) liquid sodium and (b) liquid tin. Fullsize ImageView full abstractDownload PDF (6861K) Full view HTML -

Hitoshi Fukuoka, Xinsheng Huang, Kazutaka Suzuki, Yuhki Tsukada, Toshi ...Article type: Regular Article

2021 Volume 85 Issue 3 Pages 120-127

Published: March 01, 2021

Released on J-STAGE: February 25, 2021

Advance online publication: February 05, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLEffect of rolling temperature on room temperature formability and texture formation of Mg-3 mass%Al-1 mass%Sn (AT31) alloy sheet was investigated, and compared with the results of Mg-3 mass%Al-1 mass%Zn (AZ31) alloy sheet. When the rolling temperature was set to a high temperature (798 K), AT31 alloy showed almost the same basal texture intensity as AZ31 alloy rolled at the same condition. When the rolling temperature was set to a low temperature (723 K), AT31 alloy showed lower basal texture intensity than AZ31 alloy rolled at the same condition. As a result of Erichsen test, when the rolling temperature was set to 798 K, AT31 alloy exhibited excellent Erichsen value more than 8.8 mm, which corresponded to AZ31 alloy rolled at the same condition. On the other hand, when the rolling temperature was set to 723 K, AT31 alloy exhibited higher Erichsen value (6.7 mm) than that of AZ31 alloy (4.5 mm). The variations in Erichsen values with differences in alloy composition and rolling temperature were closely related to the variations in basal texture intensity. Recrystallization behavior of AT31 alloy during the initial stage of the final annealing was investigated. It is found that recrystallization mainly occurred at grain boundaries, and grains with more random orientation were recrystallized, when the rolling temperature was set to 798 K. Mechanisms of recrystallization and random texture formation were almost the same with those of AZ31 alloy. The reason why AT31 alloy rolled at 723 K exhibited more random texture than AZ31 rolled at the same condition is that grains with more random orientation were recrystallized at grain boundaries during the final annealing.

Fig. 4 (a) Relationship between Erichsen value and final rolling temperature of rolled AT31 and AZ31 alloys24) and (b) images of the results of Erichsen tests of AT31 alloys finally rolled at 723 K and 798 K. Fullsize ImageView full abstractDownload PDF (8986K) Full view HTML

Fig. 4 (a) Relationship between Erichsen value and final rolling temperature of rolled AT31 and AZ31 alloys24) and (b) images of the results of Erichsen tests of AT31 alloys finally rolled at 723 K and 798 K. Fullsize ImageView full abstractDownload PDF (8986K) Full view HTML

- |<

- <

- 1

- >

- >|