- |<

- <

- 1

- >

- >|

-

Takayuki Ichikawa, Hiroki Miyaoka, Makoto Hino, Keitaro Horikawa, Teru ...Article type: Preface

2023 Volume 87 Issue 4 Pages 95

Published: April 01, 2023

Released on J-STAGE: March 25, 2023

JOURNAL FREE ACCESS FULL-TEXT HTMLDownload PDF (286K) Full view HTML -

Ryo Kawakami, Kazumasa KubotaArticle type: Regular Article

2023 Volume 87 Issue 4 Pages 96-102

Published: April 01, 2023

Released on J-STAGE: March 25, 2023

JOURNAL FREE ACCESS FULL-TEXT HTMLThe mechanical and fatigue properties of 18Cr-4.8Ni-0.03C stainless steel were measured under high-pressure gaseous hydrogen. Slow-strain-rate tensile (SSRT) tests were carried out at temperatures of 228 K, 293 K, and 363 K under 105 MPa high-pressure gaseous hydrogen and 0.1 MPa nitrogen. The relative tensile strength was 0.98 or higher at all temperatures, confirming that this steel has good hydrogen compatibility. Rotating bending fatigue tests were carried out at room temperature under 88 MPa high-pressure gaseous hydrogen and air. Fatigue limits were found in both types of atmosphere. No deterioration of the fatigue limit was observed in the specimen tested under 88 MPa high-pressure gaseous hydrogen. Surface cracks were observed in the parallel part of the rotating bending fatigue test specimen that was unbroken at 107 cycles in both types of atmosphere.

Fig. 9 S-N data. Fullsize ImageView full abstractDownload PDF (4847K) Full view HTML

Fig. 9 S-N data. Fullsize ImageView full abstractDownload PDF (4847K) Full view HTML -

Teruto Kanadani, Makoto Hino, Keitaro Horikawa, Norihito Nagata, Keiyu ...Article type: Regular Article

2023 Volume 87 Issue 4 Pages 103-107

Published: April 01, 2023

Released on J-STAGE: March 25, 2023

Advance online publication: February 10, 2023JOURNAL FREE ACCESS FULL-TEXT HTMLIn this study, the effect of surface layer and hydrogen on the fatigue strength of Al-4%Ge alloy was investigated. As the results, the following points were clarified. (1) Tensile strength of the specimen subjected to the Ni-P plating after aging treatment or furnace cooling treatment was improved by about 10% in comparison to one of the non-processed specimens. (2) Breaking elongation of the specimen subjected to the Ni-P plating after aging treatment showed no significant changes in comparison to one of the non-processed specimens. On the other hand, breaking elongation of the specimen subjected to Ni-P plating after a furnace cooling treatment was reduced to 70% in comparison to one of the non-processed specimens. (3) Fatigue strength of the specimen subjected to the Ni-P plating after a furnace cooling treatment was overall reduced rather than one of non-processed specimens. (4) Fatigue strength of the specimen subjected to the Ni-P plating after aging treatment was overall reduced, except for the low-stress region, rather than one of the non-processed specimens. (5) In the specimen subjected to Ni-P plating after a furnace cooling treatment or aging treatment, clear hydrogen desorption was recognized. On the other hand, there was only hydrogen desorption from a few of the non-processed specimens. Especially, it is considered that the poor fatigue strength and ductility of the plating materials are mainly due to the interaction between the surface precipitates and hydrogen gas.

Fig. 3 Relations between stress (σ) and number of cycles to failure (N) for specimens; ● plated or ○ not plated after aging. In addition, △ Electro-polished. Fullsize ImageView full abstractDownload PDF (1196K) Full view HTML

Fig. 3 Relations between stress (σ) and number of cycles to failure (N) for specimens; ● plated or ○ not plated after aging. In addition, △ Electro-polished. Fullsize ImageView full abstractDownload PDF (1196K) Full view HTML -

Keitaro Horikawa, Hideki Kuwata, Naoki Fukumuro, Makoto HinoArticle type: Regular Article

2023 Volume 87 Issue 4 Pages 108-113

Published: April 01, 2023

Released on J-STAGE: March 25, 2023

Advance online publication: January 27, 2023JOURNAL FREE ACCESS FULL-TEXT HTMLIn the present study, the effect of electro zinc plating on environmental hydrogen embrittlement of 7075-T6 aluminum alloys was investigated by using a slow strain rate testing device which can detect quantitively the amount of hydrogen generated during deformation and fracture. The testing device can also detect traces of hydrogen gas as low as 5 ppb by using a semiconductor gas sensor at ambient pressure. It was revealed that the environmental hydrogen embrittlement of 7075-T6 aluminum alloys was highly suppressed by zinc-based electroplating, while not fully by anodization. The suppression of the hydrogen embrittlement by zinc plating was caused by the protection of original aluminum surfaces during plastic deformation.

Fig. 6 Hydrogen release during SSRT of 7075-T6 aluminum alloys. (a): Zn-plated (wet), (b): anodized (wet). Fullsize ImageView full abstractDownload PDF (3845K) Full view HTML

Fig. 6 Hydrogen release during SSRT of 7075-T6 aluminum alloys. (a): Zn-plated (wet), (b): anodized (wet). Fullsize ImageView full abstractDownload PDF (3845K) Full view HTML -

Makoto Hino, Ryohei Shinno, Kota Kawaue, Ryoichi Kuwano, Koji Monden, ...Article type: Regular Article

2023 Volume 87 Issue 4 Pages 114-119

Published: April 01, 2023

Released on J-STAGE: March 25, 2023

JOURNAL FREE ACCESS FULL-TEXT HTMLIn this study, 6061-T6 aluminum alloys were plated with electroless Ni-P with different phosphorus content and three-point bending and rotary bending fatigue tests. The effects of hydrogen due to plating on mechanical properties were investigated. It was shown that the ductility decreased immediately after low-phosphorus type and high-phosphorus type Ni-P plating by three-point bending test because a hydrogen was introduced into the alloys. The fatigue strength of the low-phosphorus type Ni-P plated specimen was higher than that of the untreated specimen, while that of the high-phosphorus type plated specimen was much lower. It is clear that the fatigue strength differs greatly depending on the phosphorus content in the plating film. 6061-T6 aluminum alloy have been reported to exhibit no hydrogen embrittlement in low strain rate tensile tests under wet condition. However, it was found that hydrogen embrittlement occurred when 6061-T6 aluminum alloy was plated with the high-phosphorus type electroless Ni-P and fatigue-tested on rotary bending machine.

Fig. 7 Relation between stress amplitude (σa) and number of cycles to failure (N) for the un-treated, Ni-P low-P type-plated, high-P type-plated and zinc plated specimens. Fullsize ImageView full abstractDownload PDF (3784K) Full view HTML

Fig. 7 Relation between stress amplitude (σa) and number of cycles to failure (N) for the un-treated, Ni-P low-P type-plated, high-P type-plated and zinc plated specimens. Fullsize ImageView full abstractDownload PDF (3784K) Full view HTML -

Makoto Hino, Tomonari Oda, Ryohei Shinno, Kota Kawaue, Keitaro Horikaw ...Article type: Regular Article

2023 Volume 87 Issue 4 Pages 120-124

Published: April 01, 2023

Released on J-STAGE: March 25, 2023

JOURNAL FREE ACCESS FULL-TEXT HTMLZn-Ni alloy plating from sulfuric acid baths has excellent hydrogen embrittlement resistance for high strength steels. In this study, we investigated the factors that contribute to the hydrogen embrittlement resistance of Zn-Ni alloy plating. In Zn-Ni alloy plating, microcracks are formed in the coating. Hydrogen embrittlement was accelerated by mechanical sealing of these microcracks, and the microcracks that form in the coating were a pathway for hydrogen release. Therefore, these microcracks are found to play an extremely important role in suppressing hydrogen embrittlement. It is suggested that a gap in the plating film that can release hydrogen-induced vacancies is important to suppress hydrogen embrittlement due to plating.

Fig. 6 Cross-sectional observation of Zn-Ni alloy plating film by FIB. Fullsize ImageView full abstractDownload PDF (1727K) Full view HTML

Fig. 6 Cross-sectional observation of Zn-Ni alloy plating film by FIB. Fullsize ImageView full abstractDownload PDF (1727K) Full view HTML

-

Hikaru Sato, Kazumune Sasaki, Michihisa Fukumoto, Hiroki TakahashiArticle type: Regular Article

2023 Volume 87 Issue 4 Pages 125-131

Published: April 01, 2023

Released on J-STAGE: March 25, 2023

JOURNAL FREE ACCESS FULL-TEXT HTMLIn recently years, hydrogen production by water electrolysis using renewable energy is promoted from a carbon-neutral perspective. However, hydrogen is difficult to store and transport, and low volumetric energy density. Therefore, ammonia obtained by the Haber-Bosch process is attracting much attention as an energy carrier because of its easy liquefaction and handling. Ammonia is toxic, but it can be detected easily if ammonia leaks outside owing to its characteristic smell. Thus, a direct ammonia fuel cells (DAFCs) that use ammonia as fuel is promising candidate as a new power generation system. Generally, Pt is used as anode catalyst for ammonia oxidation reaction in DAFC. But it is desired to develop an alternative catalyst for DAFC anode due to the price escalation of Pt, limitation of Pt reserves and the problems of inactivation caused by Nads poisoning on Pt. Therefore, Pt-Mo alloy catalyst was prepared by RF-magnetron sputtering and the ammonia oxidation activity was investigated in this study. Pt-Mo alloy catalysts showed higher ammonia oxidation activity than Pt one. Especially, Pt-44.0at%Mo indicated 31.4 mA cm−2 and it is the highest activity among Pt-Mo alloys. And then, Pt-44.0at%Mo is promising candidate for anode catalyst of DAFC.

Fig. 5 Ammonia oxidation activity of Pt, Pt-19.7at%Mo, Pt-44.0at%Mo and Pt-90.8at%Mo thin films. Fullsize ImageView full abstractDownload PDF (3351K) Full view HTML

Fig. 5 Ammonia oxidation activity of Pt, Pt-19.7at%Mo, Pt-44.0at%Mo and Pt-90.8at%Mo thin films. Fullsize ImageView full abstractDownload PDF (3351K) Full view HTML -

Kyohei Numakura, Kazumasa Ohtaka, Takeshi Murakami, Kazuyuki Shimizu, ...Article type: Regular Article

2023 Volume 87 Issue 4 Pages 132-138

Published: April 01, 2023

Released on J-STAGE: March 25, 2023

Advance online publication: January 20, 2023JOURNAL FREE ACCESS FULL-TEXT HTMLThe microstructures, Vickers hardness, and electromagnetic properties of the automotive die-quenched steel were investigated under various die temperatures. The positive correlations between hardness and the coercivity of magnetic hysteresis loop and between hardness and electrical resistance were confirmed above the hardness of HV370. EBSD and TEM observations reveal that the die-quenched steels contain both fresh martensite and auto-tempered martensite due to the high martensite transformation temperature of the steel. Neural network analysis shows an increase of auto-tempered martensite with increasing die-temperature, which causes the positive correlation. This study demonstrates the usefulness of nondestructive electromagnetic evaluation of the hardness in die-quenched automotive steel components during manufacturing process.

Fig. 5 Relation between hardness and coercivity of the DQ steels. Fullsize ImageView full abstractDownload PDF (6569K) Full view HTML

Fig. 5 Relation between hardness and coercivity of the DQ steels. Fullsize ImageView full abstractDownload PDF (6569K) Full view HTML -

Haruki Yamane, Takashi Hasegawa, Yukiko Yasukawa, Masanobu KobayashiArticle type: Regular Article

2023 Volume 87 Issue 4 Pages 139-147

Published: April 01, 2023

Released on J-STAGE: March 25, 2023

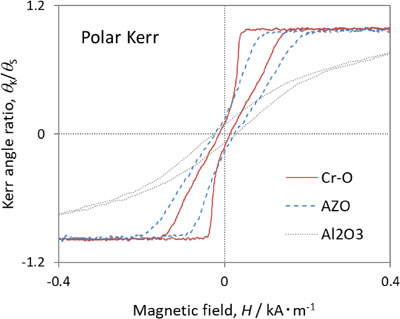

JOURNAL FREE ACCESS FULL-TEXT HTMLThe influence of oxide seed layers on the magnetic properties and crystalline structures of hcp-Co80Pt20 perpendicular magnetic thin films were investigated for magneto-optical chemical and biological sensing system. Cr-O, Al-doped ZnO (AZO) and Al2O3 films were used as the oxide seed layers. The Cr-O layer was most effective to improve the perpendicular magnetic properties of Co-Pt. The Cr-O seed layer produced the largest values of the interfacial perpendicular magnetic anisotropy (KS) and perpendicular magnetocrystalline anisotropy (KV). The investigation in the crystalline and chemical bonding conditions suggested that the both perpendicular magnetic anisotropies were originated from the interaction of Co and oxide at the Co-Pt/Cr-O interface. The improvements of KS and KV on the Cr-O seed layer are attributed to the hybridization of Co-3d and O-2p orbits and the hcp(001)-CoPt crystal growth with self-orientation, respectively. We also demonstrated the magneto-optical cavity effect on the Co-Pt perpendicular magnetic stacked films with the Cr-O intermediate layer. The stacked films indicated a large magneto-optical response by optical interference and good perpendicular magnetic properties with an ideal square shaped hysteresis loop.

Fig. 1 Magneto-optical polar Kerr loops for Co-Pt stacked films with oxide seed layers of Cr-O (red solid line), AZO (blue dashed line) and Al2O3 (black dotted line). The thicknesses of Co-Pt and oxide seed layers were 14.9 nm and 30 nm, respectively. The Kerr rotation angles (θK) were normalized by the saturation Kerr angle (θS) of each sample, and all hysteresis loops were measured at a wavelength of 400 nm. Fullsize ImageView full abstractDownload PDF (5614K) Full view HTML

Fig. 1 Magneto-optical polar Kerr loops for Co-Pt stacked films with oxide seed layers of Cr-O (red solid line), AZO (blue dashed line) and Al2O3 (black dotted line). The thicknesses of Co-Pt and oxide seed layers were 14.9 nm and 30 nm, respectively. The Kerr rotation angles (θK) were normalized by the saturation Kerr angle (θS) of each sample, and all hysteresis loops were measured at a wavelength of 400 nm. Fullsize ImageView full abstractDownload PDF (5614K) Full view HTML

- |<

- <

- 1

- >

- >|