- |<

- <

- 1

- >

- >|

-

Nobuo NakadaArticle type: Overview

2019 Volume 83 Issue 12 Pages 449-457

Published: December 01, 2019

Released on J-STAGE: November 25, 2019

Advance online publication: October 21, 2019JOURNAL FREE ACCESS FULL-TEXT HTMLMartensitic reversion from bcc-martensite to fcc-austenite is an important phase transformation to improve mechanical properties of steels remarkably as well as other phase transformations. However, few studies have undertaken to investigate the martensitic reversion, because it hardly occurs in carbon steels. In the present overview, some characteristics of the martensitic reversion were explained briefly with reference to the previous studies, and a couple of applications of microstructural control for high alloy steels using the martensitic reversion were introduced. Furthermore, a novel heat treatment through the martensitic reversion to improve strength and toughness of low alloy martensitic steel was proposed.

Fig. 7 EBSD data, (a-d) inverse pole figure, (e) phase and (f-h) kernel average misorientation maps, showing recrystallization of martensitic reversed austenite by bulge mechanism in Fe-32%Ni-5%Co cast alloy, which were after (a, e) sub-zero treatment at 77 K and annealing at (b, f) 923, (c, g) 1073 and (d, h) 1173 K. Fullsize ImageView full abstractDownload PDF (5851K) Full view HTML

Fig. 7 EBSD data, (a-d) inverse pole figure, (e) phase and (f-h) kernel average misorientation maps, showing recrystallization of martensitic reversed austenite by bulge mechanism in Fe-32%Ni-5%Co cast alloy, which were after (a, e) sub-zero treatment at 77 K and annealing at (b, f) 923, (c, g) 1073 and (d, h) 1173 K. Fullsize ImageView full abstractDownload PDF (5851K) Full view HTML

-

Momoka Watanabe, Hiromoto Kitahara, Yohei Takamatsu, Masayuki Tsushida ...Article type: Regular Article

2019 Volume 83 Issue 12 Pages 458-464

Published: December 01, 2019

Released on J-STAGE: November 25, 2019

Advance online publication: October 11, 2019JOURNAL FREE ACCESS FULL-TEXT HTMLPure Mg, Mg-0.5 at%Al, Mg-0.5 at%Zn, Mg-0.5 at%Y, Mg-0.9 at%Y, and pure Zn single crystals were applied to indentation tests using a spherical indenter to allow experimental investigation the roles both slips and twinning induce on the formation of indentation. When indented on (0001), all single crystals displayed indentation of circular morphology without slip lines and twins. Mg and Mg alloys' indentation sizes were found dependent on critical resolved shear stress (CRSS) for basal slip in (0001) indentations. Zn (0001) indentation size depends on CRSS for both basal and pyramidal slips. Conversely, when indented on (1010) and (1210), all single crystals had indentations elongated to [0001] with basal slip lines around indentations. Also, {1012} twins were observed in Mg-0.5 at%Al and Mg-0.5 at%Zn but were scarce in Mg-Y. Pure Zn displayed second order pyramidal slips. Sizes of both (1010) and (1210) indentations were found dependent on CRSS for basal slips and for {1012} twins.

Fig. 3 Optical micrographs of indentations on (1-210) in (a) Mg, (b) 05Al, (c) 05Zn, (d) 05Y, (e) 09Y and (f) Zn single crystals when indented at 4.90 N. Fullsize ImageView full abstractDownload PDF (1876K) Full view HTML

Fig. 3 Optical micrographs of indentations on (1-210) in (a) Mg, (b) 05Al, (c) 05Zn, (d) 05Y, (e) 09Y and (f) Zn single crystals when indented at 4.90 N. Fullsize ImageView full abstractDownload PDF (1876K) Full view HTML -

S. Yamamoto, Y. Miyajima, C. Watanabe, R. Monzen, T. Tsuru, H. MiuraArticle type: Regular Article

2019 Volume 83 Issue 12 Pages 465-473

Published: December 01, 2019

Released on J-STAGE: November 25, 2019

JOURNAL FREE ACCESS FULL-TEXT HTMLStrain-rate dependencies of deformation behavior of commercial purity titanium specimens having different grain sizes were systematically investigated. Ultrafine-grained titanium with an average grain size of 0.07 µm (UFG-Ti) fabricated by multi-directional forging followed by conventional thermo-mechanical processing, and fine-grained (FG-Ti) and coarse-grained (CG-Ti) specimens with an average grain sizes of 0.8 µm and 12 µm attained by its, respectively, annealing at 773 K and 973 K for 1.8 ks were prepared. The FG- and UFG-Ti specimens exhibited strong strain-rate dependence of 0.2% proof stress, while that of CG-Ti ones were almost constant regardless of applied strain-rate. In-situ X-ray diffraction measurements during tensile tests were also conducted at synchrotron radiation facility, SPring-8. Using the modified Williamson-Hall and the modified Warren-Averbach methods, the activated slip systems and change in dislocation density during deformation were estimated. As a result, it was found that <a> and <c+a> slips were activated in FG- and UFG-Ti specimens. On the other hand, the activation of <c+a> slip was never observed in the CG-Ti ones. It can be, thus, concluded that the different strain-rate dependency of deformation behaviors of specimens with different grain sizes were ascribed to the difference in the deformation mechanisms.

Graphical Abstract Fullsize ImageView full abstractDownload PDF (3595K) Full view HTML

Graphical Abstract Fullsize ImageView full abstractDownload PDF (3595K) Full view HTML -

Tetsuya Okuyama, Takumi Higashizono, Ngo Huynh Kinh Luan, Masaki KudoArticle type: Regular Article

2019 Volume 83 Issue 12 Pages 474-478

Published: December 01, 2019

Released on J-STAGE: November 25, 2019

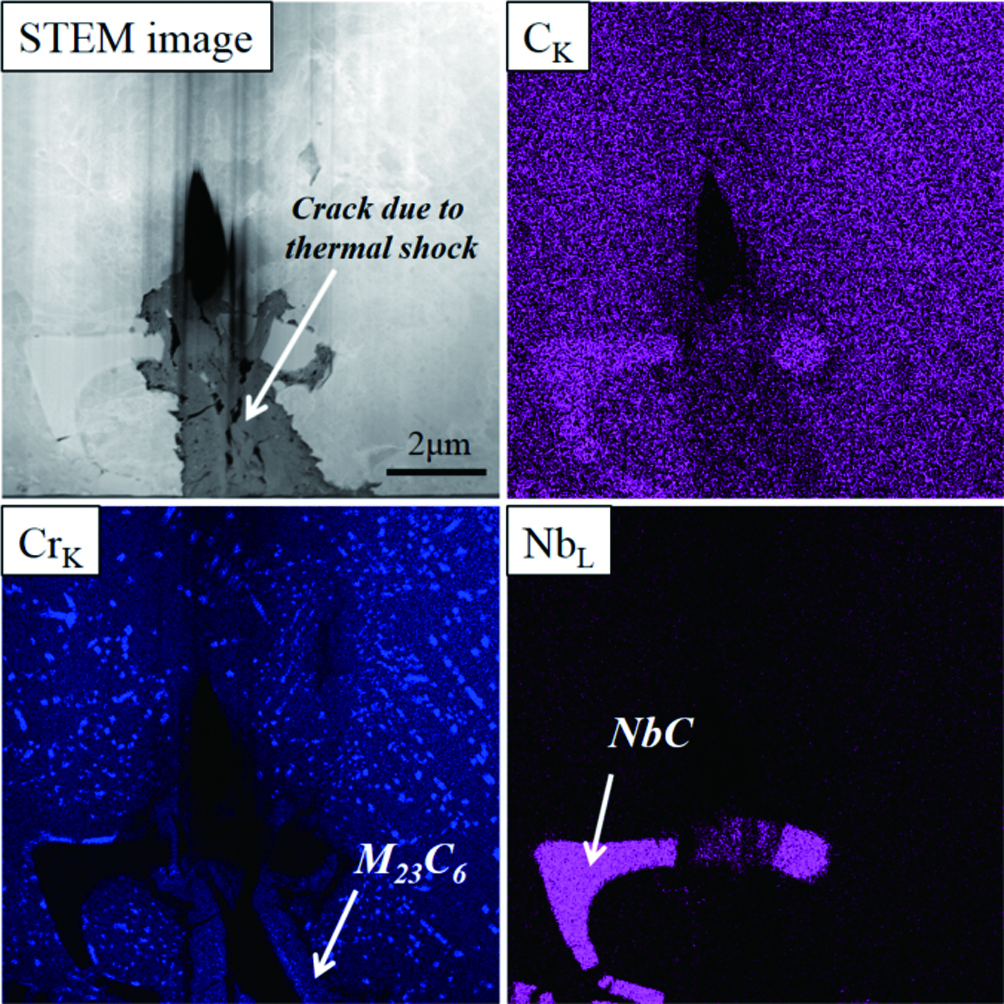

Advance online publication: October 28, 2019JOURNAL FREE ACCESS FULL-TEXT HTMLThe effect of Nb on microstructure and thermal-shock resistance was investigated for as cast and annealed JIS SCH21 steels. Primary NbC carbide were crystallized together with M23C6 at grain boundary in as cast steel. Decomposition of primary M23C6 was detected, while NbC was also hardly decomposed when annealed at elevated temperature. It was found that chromium carbides had low thermal stability but primary NbC carbides played a role in preventing propagation of micro-cracks and restraining shape deformation under condition both heating and quenching. As a result, thermal-shock resistance was improved in the Nb-added steel.

Fig. 12 Partitioning of alloying elements analyzed by STEM-EDS for micro-crack in Nb steel occurred when thermal shocked at 1223 K for 300 cycles. Fullsize ImageView full abstractDownload PDF (3246K) Full view HTML

Fig. 12 Partitioning of alloying elements analyzed by STEM-EDS for micro-crack in Nb steel occurred when thermal shocked at 1223 K for 300 cycles. Fullsize ImageView full abstractDownload PDF (3246K) Full view HTML

-

Nobuya Banno, Taro Morita, Zhou Yu, Tsuyoshi Yagai, Kyoji Tachikawa2019 Volume 83 Issue 12 Pages 479-480

Published: December 01, 2019

Released on J-STAGE: November 25, 2019

JOURNAL FREE ACCESSDownload PDF (765K)

- |<

- <

- 1

- >

- >|