- Issue 5 Pages 91-

- Issue 4 Pages 69-

- Issue 3 Pages 39-

- Issue 2 Pages 27-

- Issue 1 Pages 1-

- |<

- <

- 1

- >

- >|

-

Hiroyuki Iwata, Hiroyasu SakaArticle type: Overview

2024 Volume 88 Issue 4 Pages 69-80

Published: April 01, 2024

Released on J-STAGE: March 25, 2024

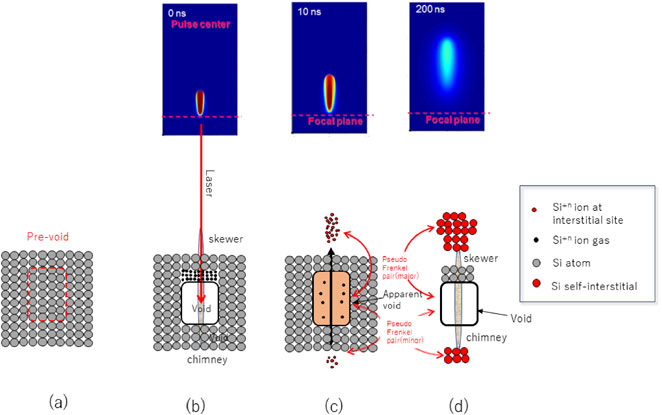

Advance online publication: January 19, 2024JOURNAL FREE ACCESS FULL-TEXT HTMLSi is opaque to visible light, but transparent to infrared rays. Therefore, when the infrared laser is focused inside Si, the focal portion becomes ultra-hot, and a modified volume (Laser induced modified volume: LIMV) is generated inside. After the laser beam is injected into the Si wafer at equal intervals (for example, 5 µm) in the cross direction, and then a force is applied from the outside. Then, cracking originates from LIMV occurs, and the Si wafer is divided into small pieces of 5 µm square. This is the stealth dicing (SD) technology, which is now widely used in the manufacture of semiconductor devices. In this process, clarifying the nature of LIMV is of great industrial and academic significance. The authors have been engaged in elucidating the mechanism of LIMV development by TEM observation. This phenomenon, which at first seemed extremely puzzling, was finally elucidated. In this overview, we would like to describe the process that led to this elucidation in chronological order. This phenomenon is extremely strange, and due to the author's lack of knowledge, there were errors in the contents of the papers published so far, so we have corrected them in this overview.

Fig. 20 Giant pseudo Frenkel pair. Upper part is reproduced with permission from Ref. 10). Fullsize ImageView full abstractDownload PDF (12767K) Full view HTML

Fig. 20 Giant pseudo Frenkel pair. Upper part is reproduced with permission from Ref. 10). Fullsize ImageView full abstractDownload PDF (12767K) Full view HTML

-

Atsutaka Hayashi, Nobuhiko Hiraide, Jun-ichi Hamada, Yoshiharu InoueArticle type: Regular Article

2024 Volume 88 Issue 4 Pages 81-89

Published: April 01, 2024

Released on J-STAGE: March 25, 2024

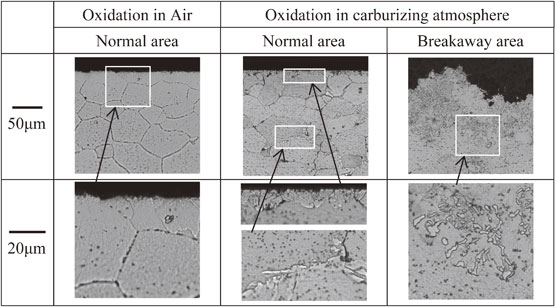

JOURNAL FREE ACCESS FULL-TEXT HTMLStainless steel is used as a heat-resistant material not only in air, but also in carburizing atmospheres containing CO and CO2. Carburization may cause austenization for ferritic stainless steels. In this study, the high-temperature oxidation behaviors of 17% Cr ferritic stainless steels with and without the addition of austenite-forming elements, such as Cu and Ni, in a carburizing atmosphere at 1123 K were investigated. The steels did not exhibit breakaway oxidation in the temperature range of 1123-1273 K in air. However, doping the steels with Cu and Ni enhanced breakaway oxidation in a carburizing atmosphere at 1123 K. Traces of austenization and carburization were observed at the base metal under the breakaway oxidation scale of the 17% Cr steel doped with 1% Cu and 1% Ni. Thus, it is proposed that the breakaway oxidation of the ferritic stainless steels in a carburizing atmosphere is attributed to austenization induced by carburization and doping with austenite-forming elements.

Fig. 9 Micro-structures of 1Cu-1Ni steels oxidized at 1123 K for 720 ks in air and at 1123 K for 360 ks in a carburizing atmosphere. Fullsize ImageView full abstractDownload PDF (6089K) Full view HTML

Fig. 9 Micro-structures of 1Cu-1Ni steels oxidized at 1123 K for 720 ks in air and at 1123 K for 360 ks in a carburizing atmosphere. Fullsize ImageView full abstractDownload PDF (6089K) Full view HTML

- |<

- <

- 1

- >

- >|