- |<

- <

- 1

- >

- >|

-

Naohiro Kobayashi, Motomichi Koyama, Kenji Kobayashi, Tomohiko Hojo, E ...Article type: Regular Article

2021 Volume 85 Issue 2 Pages 49-58

Published: February 01, 2021

Released on J-STAGE: January 25, 2021

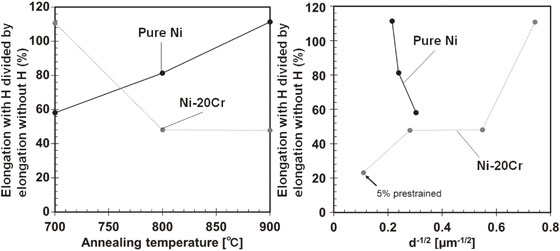

Advance online publication: December 25, 2020JOURNAL FREE ACCESS FULL-TEXT HTMLThe grain size effects on the hydrogen embrittlement susceptibility of pure Ni and Ni-20Cr alloy were investigated. The hydrogen embrittlement susceptibility was evaluated by tensile testing under electrochemical hydrogen charging. Relative elongation, defined as the elongation under hydrogen charging divided by elongation in air, increased with increasing grain size in pure Ni (the grain size was in the range of 11-22 µm). In contrast, the relative elongation of Ni-20Cr alloy increased with decreasing grain size from 13 to 1.8 µm. Correspondingly, intergranular fracture was suppressed by grain coarsening in pure Ni and grain refinement in the Ni-20Cr alloy. In addition, the intergranular fracture surface in pure Ni showed curved slip lines, and in the Ni-20Cr alloy showed straight line marks. These fractographic features imply that the mechanisms of the hydrogen-assisted intergranular crack growth were different in pure Ni and Ni-20Cr alloy and this can be attributed to the difference in stacking fault energy.

View full abstractDownload PDF (8147K) Full view HTML

View full abstractDownload PDF (8147K) Full view HTML -

Kenta Fukumoto, Satoshi Oue, Tsukasa Niwa, Yoshiharu Kikuchi, Shinya A ...Article type: Regular Article

2021 Volume 85 Issue 2 Pages 59-66

Published: February 01, 2021

Released on J-STAGE: January 25, 2021

Advance online publication: December 18, 2020JOURNAL FREE ACCESS FULL-TEXT HTMLElectrodeposition of Zn was performed on an Fe electrode at a current density of 50-5000 A·m−2 and a charge of 4 × 104 C·m−2 in an unagitated zincate solution at 313 K containing 0.62 mol·dm−3 of ZnO, 4.0 mol·dm−3 of KOH or NaOH, and organic additives. The effects of KOH and NaOH on the deposition behavior of Zn in solution containing organic additives and the microstructure of the deposits were investigated. In solution containing a quaternary ammonium cation (PQ) and a quaternary ammonium salt with a benzene ring (QA), the current efficiency for Zn deposition at high current density region of 1000 to 5000 A·m−2 to produce the glossy films was higher with KOH than that with NaOH. At high current densities above 1000 A·m−2, Zn deposition approaches the diffusion limitation of ZnO22− ions. With additions of PQ and QA, the diffusion of ZnO22− ions was significantly suppressed, and the degree of suppression was smaller with KOH than that with NaOH. The polarization resistance at 200 A·m−2 investigated by AC impedance revealed that the adsorption ability of PQ and QA onto the cathode was smaller with KOH than that with NaOH. Since the suppression effect of additives on the Zn deposition is smaller with KOH than that with NaOH, the current efficiency for Zn deposition at high current density region is larger with KOH. The upper limit of current density to produce the glossy films was smaller with KOH than that with NaOH, and the spongy thin films were partially observed on the platelets crystals obtained at high current density in KOH solution. The content of C resulting from the additives in deposited Zn was smaller with KOH. These phenomena are attributed to the adsorption ability of PQ and QA onto the cathode being smaller with KOH.

Fig. 6 Current efficiency for Zn deposition from the KOH and NaOH solutions with and without additives. [● KOH without additive, ▲ KOH with PQ and QA, ○ NaOH without additive, △ NaOH with PQ and QA] Fullsize ImageView full abstractDownload PDF (3299K) Full view HTML

Fig. 6 Current efficiency for Zn deposition from the KOH and NaOH solutions with and without additives. [● KOH without additive, ▲ KOH with PQ and QA, ○ NaOH without additive, △ NaOH with PQ and QA] Fullsize ImageView full abstractDownload PDF (3299K) Full view HTML -

Hirokazu Sato, Nozomu Adachi, Yoshikazu TodakaArticle type: Regular Article

Hirokazu Sato, Nozomu Adachi, Yoshikazu TodakaArticle type: Regular Article

2021 Volume 85 Issue 2 Pages 67-74

Published: February 01, 2021

Released on J-STAGE: January 25, 2021

JOURNAL FREE ACCESS FULL-TEXT HTMLThe effect of one-pass strain, |±Δε|, on grain refinement was systematically investigated by cyclic - HPT straining with a repetitive deformation process in which positive and negative shear strain are introduced. The steady-state grain size, dss, depended on |±Δε| rather than the given total strain, Σ |±Δε|. The unstable dislocation cell walls formed by positive strain, +Δε, was discomposed by negative strain, −Δε. The stability of dislocation cell wall increased as the number of dislocations introduced by applying |±Δε| in a grain, n, increased. The decrease in n was caused by decreasing +Δε and grain size. It was found that n affected the stability of dislocation cell walls and was an important factor in determining dss.

Fig. 7 Relationship between the number of dislocations introduced by one-pass strain |±Δε| in one grain n and grain size d. The n at the steady-state grain size dss in c-HPT (|±Δε| < 3) were plotted. Each |±Δε| is indicated by a color in the color bar. Fullsize ImageView full abstractEditor's pick

Fig. 7 Relationship between the number of dislocations introduced by one-pass strain |±Δε| in one grain n and grain size d. The n at the steady-state grain size dss in c-HPT (|±Δε| < 3) were plotted. Each |±Δε| is indicated by a color in the color bar. Fullsize ImageView full abstractEditor's pickYoung Author Best Paper Award 2022

Download PDF (3695K) Full view HTML -

Gaku Kitahara, Hideaki Matsuoka, Takashi AsadaArticle type: Regular Article

2021 Volume 85 Issue 2 Pages 75-83

Published: February 01, 2021

Released on J-STAGE: January 25, 2021

Advance online publication: December 25, 2020JOURNAL FREE ACCESS FULL-TEXT HTMLAutomobile manufacturers are accelerating adoption of spot welding of Advanced High-Strength-Steels (AHSS) sheets to reduce weight of automobile bodies. Rapid evaluation of the hydrogen embrittlement (HE) resistance for the spot-welds of AHSS sheets is required, since it is worried that the HE resistance of the nugget will deteriorate compared to the base metal due to the difference in microstructure caused by rapid cooling and solidification during spot welding. However, evaluation of the HE resistance for the spot-welds have not been established. In this study, we prepared spot-welded specimens using AHSS sheets and performed tensile shear tests with varying tensile rates under hydrogen charging to evaluate the relationship between diffusible hydrogen content and tensile shear strength. As a result, the tensile shear strength of spot welds decreased as the amount of diffusible hydrogen increased. The quasi-cleavage fractured surface and intergranular fractured surface were observed at the nugget and inside the crack generated at the nugget-heat affected zone interface. Furthermore, as the results of crack growth behavior and hydrogen thermal desorption spectroscopy analysis, hydrogen embrittlement in spot welds can be attributed to the stress-induced diffusion of hydrogen and the hydrogen trapped in dislocation and vacancy clusters at the crack tip.

Illustration of the method used to evaluate hydrogen embrittlement resistance and the relationship between diffusible hydrogen content, tensile shear strength and fracture surfaces. Fullsize ImageView full abstractDownload PDF (4759K) Full view HTML

Illustration of the method used to evaluate hydrogen embrittlement resistance and the relationship between diffusible hydrogen content, tensile shear strength and fracture surfaces. Fullsize ImageView full abstractDownload PDF (4759K) Full view HTML

-

Yoshihiko Hangai, Mizuki Ando, Ryosuke Suzuki, Masaaki Matsubara, Taka ...Article type: Express Rapid Publication

2021 Volume 85 Issue 2 Pages 84-87

Published: February 01, 2021

Released on J-STAGE: January 25, 2021

Advance online publication: January 08, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLIn this study, three-layered porous aluminum consisting of AC4CH (porosity: 70%) / pure aluminum (80%) / A6061 (75%) / and AC4CH (70%) / pure aluminum (70%) / A6061 (70%) were fabricated by a sintering and dissolution process. When plateau stress of each layer was significantly different, such as three-layered porous aluminum with varying porosities, exhibited clear multiple plateau regions corresponding to the deformation of each layer. In contrast, when plateau stress of each layer had a close value, such as three-layered porous aluminum with homogeneous porosities, exhibited no clear multiple plateau regions.

Fig. 4 (a) Deformation behavior and (b) stress-strain curves of three-layered porous aluminum (Sample A) and corresponding uniform porous aluminum. Fullsize ImageView full abstractDownload PDF (1611K) Full view HTML

Fig. 4 (a) Deformation behavior and (b) stress-strain curves of three-layered porous aluminum (Sample A) and corresponding uniform porous aluminum. Fullsize ImageView full abstractDownload PDF (1611K) Full view HTML

- |<

- <

- 1

- >

- >|