- |<

- <

- 1

- >

- >|

-

Shunsuke YagiArticle type: Review

2021Volume 85Issue 10 Pages 367-374

Published: October 01, 2021

Released on J-STAGE: September 25, 2021

Advance online publication: August 06, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLResearch and development of innovative energy storage and conversion devices are being actively pursued, such as supercapacitors, metal-air batteries, fuel cells, redox flow batteries, and rechargeable batteries using ions other than lithium ions as carrier ions. This review describes in detail the advantages and disadvantages of magnesium rechargeable batteries using magnesium ions as carrier ions. In addition, the key points of electrolyte development are explained. Furthermore, the progress and future challenges of electrolyte research, one of the most important elements of magnesium rechargeable batteries, are discussed in detail.

Fig. 3 Schematic diagram and photograph of a typical electrolytic cell. Experiments are conducted in an Ar atmosphere glove box with water and oxygen removed to prevent water contamination in the electrolyte and the oxidation of magnesium metal. The temperature is raised as necessary to accelerate the diffusion of magnesium ions. Fullsize ImageView full abstractDownload PDF (5186K) Full view HTML

Fig. 3 Schematic diagram and photograph of a typical electrolytic cell. Experiments are conducted in an Ar atmosphere glove box with water and oxygen removed to prevent water contamination in the electrolyte and the oxidation of magnesium metal. The temperature is raised as necessary to accelerate the diffusion of magnesium ions. Fullsize ImageView full abstractDownload PDF (5186K) Full view HTML

-

Yoshiki Handa, Petros AbrahaArticle type: Regular Article

2021Volume 85Issue 10 Pages 375-381

Published: October 01, 2021

Released on J-STAGE: September 25, 2021

Advance online publication: July 16, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLThe wear rate of the expanded austenite phase formed by low-temperature plasma nitriding treatment determines the lifetime of the treated stainless steel components. In this research, austenitic stainless steel (AISI304) samples were plasma nitrided between 1 h and 24 h at a temperature of 400℃, a pressure of 1.0 Pa (25% N2 and 75% H2) gas ambiance. The expanded austenite phase was characterized in thin layers with about the same nitrogen concentration. Characterization of the samples was performed by wavelength dispersive X-ray analysis (WDS) using Electron Probe Micro Analyzer (EPMA), X-ray diffraction (XRD), laser microscopy, and micro-Vickers hardness. The results of our experiments confirm that the wear rate of the expanded austenite phase varies with the depth from the surface. Thin layers of expanded austenitic phase with the same nitrogen concentration but formed under different treatment times showed the same wear rate. As the nitrogen concentration increased, the lattice parameters and compressive residual stresses calculated from the XRD pattern showed a logarithmic increase. The wear rate, on the other hand, decreased exponentially and reached 35 × 10−6 mm3/min at 25 at%. Finally, from the data obtained for the wear rate against the nitrogen concentration, an exponential fitting curve was established to determine the wear rate at any specific depth of the austenitic expanded phase.

Fig. 7 (a)Wear rate of different treatment time with distance from surface, (b) the relationship between wear rate and hardness of expanded austenite phase with nitrogen concentration of expanded austenite phase. Fullsize ImageView full abstractDownload PDF (1777K) Full view HTML

Fig. 7 (a)Wear rate of different treatment time with distance from surface, (b) the relationship between wear rate and hardness of expanded austenite phase with nitrogen concentration of expanded austenite phase. Fullsize ImageView full abstractDownload PDF (1777K) Full view HTML -

Hideyuki Tachi, Kazutaka Suzuki, Xinsheng Huang, Yuhki Tsukada, Toshiy ...Article type: Regular Article

2021Volume 85Issue 10 Pages 382-390

Published: October 01, 2021

Released on J-STAGE: September 25, 2021

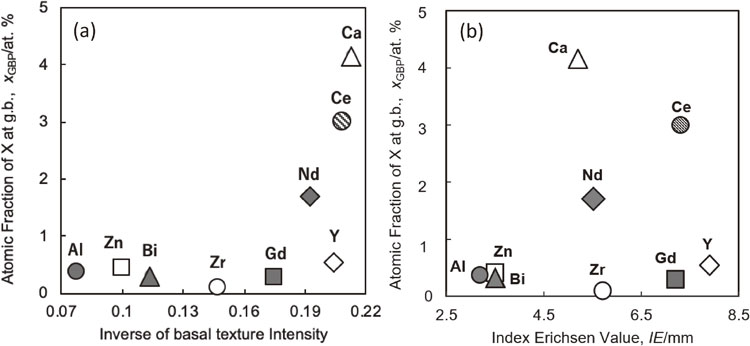

Advance online publication: August 27, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLAmounts of segregation at grain boundaries of Mg-0.05at%X (X = Al, Bi, Ca, Ce, Gd, Nd, Y, Zn, Zr) alloys were calculated by using the Hillert’s grain boundary phase model. As a result, relatively high grain boundary segregation was obtained in each case of Ca, Ce, Nd, Y and Zn. In addition, the basal plane texture and Erichsen value of the alloys were experimentally investigated, which exhibits a similar tendency to the previous experiments, i.e., the Erichsen value decreases with decreasing basal texture intensity. High-angle annular dark-field STEM (HAADF-STEM) analysis of the Mg-0.4Nd (mass%) and Mg-0.2Y (mass%) sheets elucidated that the uniform grain boundary segregation was detected in Mg-0.4Nd, while the localized and scattered segregation region was observed at grain boundary in Mg-0.2Y. These segregation behaviors were explained by the concept of critical element concentration proposed by Griffiths. An un-recrystallized grain microstructure with high lattice distortion was observed in Mg-0.4Nd in Scanning Electron Microscope - Electron Back-Scatter Diffraction (SEM-EBSD) analysis, which leads to a possibility that the grain boundary segregation of Nd contributes to the suppression of recrystallization during rolling. As the strong correlation was observed between the calculated grain boundary segregation and the experimental basal texture intensity, the amount of grain boundary segregation is a useful parameter for describing basal texture intensity of binary Mg alloys.

Fig. (a) Relationship between inverse of basal texture intensity and calculated atomic fraction of various elements in grain boundary of Mg, (b) Relationship between index Erichsen value and calculated atomic fraction of various elements in grain boundary of Mg. Fullsize ImageView full abstractDownload PDF (6918K) Full view HTML

Fig. (a) Relationship between inverse of basal texture intensity and calculated atomic fraction of various elements in grain boundary of Mg, (b) Relationship between index Erichsen value and calculated atomic fraction of various elements in grain boundary of Mg. Fullsize ImageView full abstractDownload PDF (6918K) Full view HTML -

Tomohiro Nagata, Kohei Takeda, Hiroki Adachi, Kazuhiro Ishikawa, Yoji ...Article type: Regular Article

2021Volume 85Issue 10 Pages 391-398

Published: October 01, 2021

Released on J-STAGE: September 25, 2021

Advance online publication: September 03, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLElectrical resistivity and Vickers hardness of Alloy 625 due to cold rolling were measured, and, discussed with the microstructural change obtained using electron backscattered diffraction and X-ray diffraction. Both increase in dislocation density and grain subdivision due to rolling was observed. Although the electrical resistivity of the normal pure metals increases with increasing the rolling reduction, that of Alloy 625 initially decreased with increasing the rolling reduction of 70%. Then, the electrical resistivity slightly increased with increasing the rolling reduction of 80%. Up to the rolling reduction of 70%, the reduction of electrical resistivity is associated with K effect, which is the destroy of the short-range ordered domain due to the plastic deformation. On the other hand, Vickers hardness increased with increasing the rolling reduction. It was associated with the contribution of grain refinement, dislocation, solid solution, and sort-range order strengthening.

Fig. 6 Electrical resistivity of Alloy625 measured at 77 K and 293 K depending on rolling reduction. Fullsize ImageView full abstractDownload PDF (4272K) Full view HTML

Fig. 6 Electrical resistivity of Alloy625 measured at 77 K and 293 K depending on rolling reduction. Fullsize ImageView full abstractDownload PDF (4272K) Full view HTML

- |<

- <

- 1

- >

- >|