- |<

- <

- 1

- >

- >|

-

Tsubasa Kumamoto, Motomichi Koyama, Koichi Sato, Kaneaki TsuzakiArticle type: Regular Article

2019 Volume 83 Issue 7 Pages 221-230

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: May 13, 2019JOURNAL FREE ACCESS FULL-TEXT HTMLWe studied the statistical quantitative analysis of the hydrogen-assisted damage evolution behavior from nano- to micro-scale by combining positron annihilation spectroscopy (PAS) and scanning electron microscopy (SEM)-based damage characterization in a dual-phase steel with a tensile strength of 960 MPa. The total elongation was markedly decreased by hydrogen pre-charging (0.32 mass ppm H) from 17% to 4%. We divided the damage evolution behavior into three stages: damage incubation; arrest; growth, and evaluated the effects of hydrogen pre-charging on each stage. The damage nucleation was caused by martensite fracture and enhanced by hydrogen pre-charging. However, PAS showed no enhancement of vacancy formation by hydrogen. The statistical damage quantitative analysis indicated in the damage arrest stage that the critical damage size corresponding to the blunt limit of the damage tip was decreased from ~1 μm2 in the uncharged specimen to ~0.5 μm2 in the hydrogen pre-charged specimen. The damage growth in the third stage was accelerated by hydrogen pre-charging owing to quasi-brittle damage propagation through the ferrite cleavage plane or ferrite/martensite interface. SEM observation showed that the cleavage propagation in ferrite was accompanied by the local plastic deformation. To explain this fracture acceleration, we proposed cooperative contribution of the enhancement of the local plastic deformation through adsorption-induced dislocation emission (AIDE) mechanism and the cleavage fracture through hydrogen enhanced decohesion (HEDE) mechanism.

The statistical damage quantitative analysis indicated in the damage arrest stage that the critical damage size corresponding to the blunt limit of the damage tip was 1 μm2 in the hydrogen-uncharged specimen. Fullsize ImageView full abstractDownload PDF (8741K) Full view HTML

The statistical damage quantitative analysis indicated in the damage arrest stage that the critical damage size corresponding to the blunt limit of the damage tip was 1 μm2 in the hydrogen-uncharged specimen. Fullsize ImageView full abstractDownload PDF (8741K) Full view HTML -

Masaya Nagata, Naoki Horikawa, Mie Kawabata, Kei AmeyamaArticle type: Regular Article

2019 Volume 83 Issue 7 Pages 231-237

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: May 17, 2019JOURNAL FREE ACCESS FULL-TEXT HTMLThis study aimed at investigating the influence of microstructure on mechanical properties of Harmonic Structured (HS) pure-Ni compacts. The harmonic structure is a heterogeneous microstructure with a spatial distribution of fine grains (FG) and coarse grains (CG), that is, the CG areas (‘Core’) embedded in the matrix of three-dimensionally continuously connected network of FG areas (‘Shell’). The HS pure-Ni samples were fabricated by powder metallurgy route consisting of mechanical milling (MM) of plasma rotated electrode processed pure-Ni powder and subsequent sintering by Spark Plasma Sintering. The plastic deformation at powder particle surface increases with increasing MM time. As a result, after sintering, shell fraction also increases in the HS pure-Ni samples. It was found that the fraction of a “shell” area is an important parameter controlling the balance of the mechanical properties of the HS pure-Ni compacts. The HS pure-Ni with a higher fraction of “shell” area demonstrated higher strength and approximately similar elongation as compared to the homo Ni samples and HS pure-Ni samples containing low shell fraction. Moreover, the effects of strain hardening rates and strain hardening exponents on deformation behaviour of HS pure-Ni samples were also discussed.

Fig. 8 Relationships between 0.2% proof stress, UTS and total elongation of HS (X, Y, Z) and Homo (homogeneous A, B, C, D) compacts. Fullsize ImageView full abstractDownload PDF (1340K) Full view HTML

Fig. 8 Relationships between 0.2% proof stress, UTS and total elongation of HS (X, Y, Z) and Homo (homogeneous A, B, C, D) compacts. Fullsize ImageView full abstractDownload PDF (1340K) Full view HTML -

Takayuki Kodera, Takashi OgiharaArticle type: Regular Article

2019 Volume 83 Issue 7 Pages 238-242

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

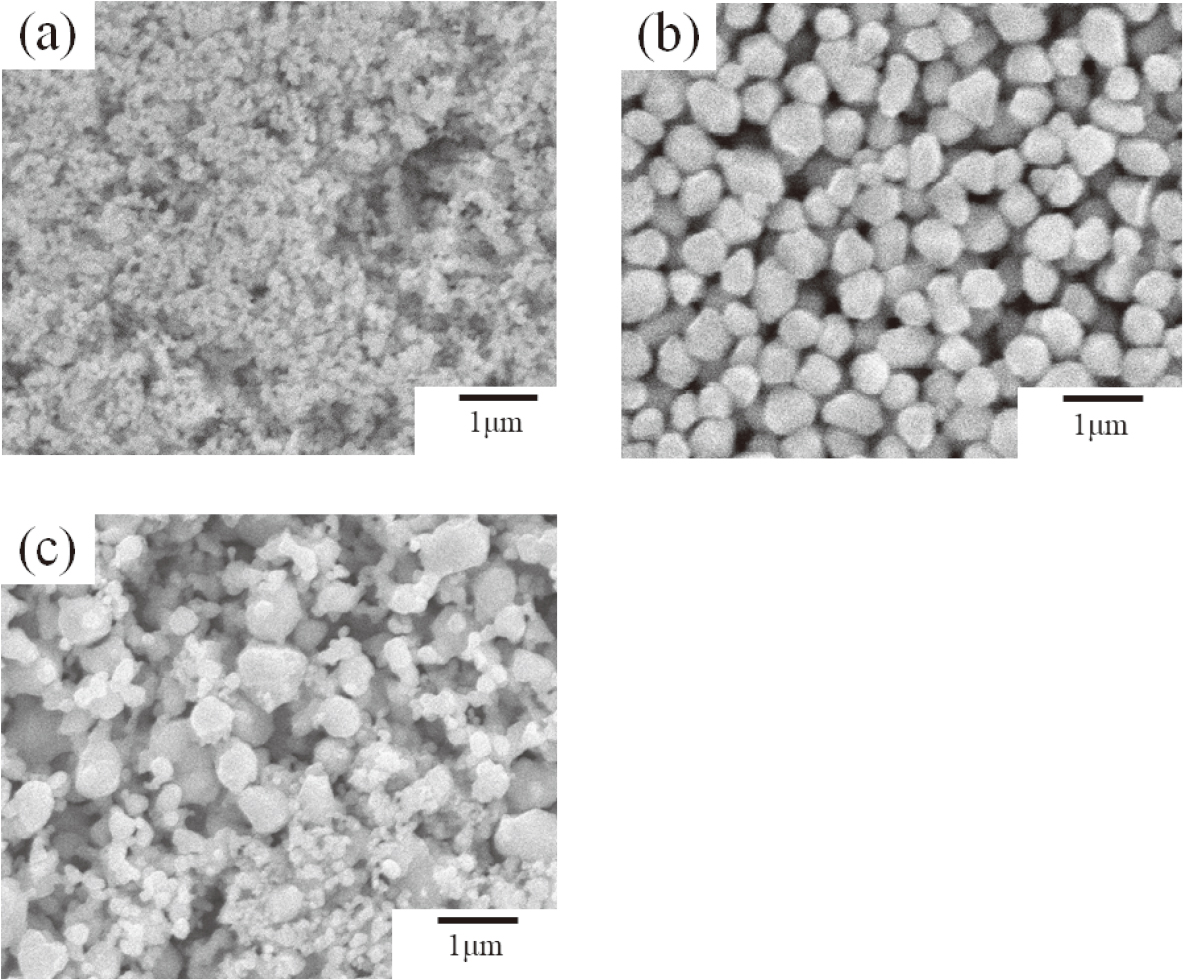

JOURNAL FREE ACCESS FULL-TEXT HTMLSilver powder was prepared through chemical reduction method using silver sulfate in sulfuric acid. Various types of reducing agent were used. When ascorbic acid was used as reducing agent, monodispersed silver particles which had uniform polyhedron morphology and high crystallinity were obtained. Monodispersed silver particles were formed when the molar ratio of ascorbic acid and silver sulfate was 1. The volume average particle size of silver powder derived from ascorbic acid was 290 nm. The thickness of gum Arabic absorbed on silver particles was 11 nm. The crystallinity of silver powder became higher so that the reduction force of reducing agent was strong. Thermal mechanical measurement showed that the shrinkage of silver paste derived from silver sulfate was lower than that of silver paste derived from silver nitrate. Electrical measurements revealed that the specific resistivity of the silver paste sintered at 900℃ for 60 min was 1.74 × 10−8 Ω m.

Fig. 1 SEM images of silver powder derived from reducing agent (a) hydrazine, (b) ascorbic acid and (c) formaldehyde. Fullsize ImageView full abstractDownload PDF (1152K) Full view HTML

Fig. 1 SEM images of silver powder derived from reducing agent (a) hydrazine, (b) ascorbic acid and (c) formaldehyde. Fullsize ImageView full abstractDownload PDF (1152K) Full view HTML -

Yoji Imai, Naomi Hirayama, Atsushi Yamamoto, Tsutomu Iida, Ken-ichi Ta ...Article type: Regular Article

2019 Volume 83 Issue 7 Pages 243-249

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

JOURNAL FREE ACCESS FULL-TEXT HTMLFirst-principles calculations were used to investigate the effects of substituting a Mg atom in Mg2Si with a foreign atom. The aim was to chemically induce a state of negative pressure for Mg2Si, which would theoretically increase its thermoelectric power factor. First, density of states (DOS) calculations were performed for Mg2Si with a Mg atom substituted with Group 3-12 elements (Sc to Zn). The results suggest that Group 3 and 4 elements are good candidates because the main features of the DOS curves for the substituted Mg2Si were the same as that of the undoped semiconductor. Structural optimization and energy calculations were then performed for Mg2Si substituted with Sc, Y, La, Ti, Zr, and Hf. Only Sc and Y showed negative energy changes as a result of the substitutional reaction. The volume changes indicate that only Y is an appropriate substitutional element for inducing a state of negative pressure for Mg2Si.

Fig. 5 Calculated band structures (BSs) of X1Mg15Si8, where X = Mg, Y, or Zr. The numbers plotted in the BS diagrams express the order counted from the bottom of the valence bands. Note that bands mainly composed of Mg2p and Y4p atomic orbitals are omitted from the numbering, although they are explicitly treated as part of the valence bands. Fullsize ImageView full abstractDownload PDF (956K) Full view HTML

Fig. 5 Calculated band structures (BSs) of X1Mg15Si8, where X = Mg, Y, or Zr. The numbers plotted in the BS diagrams express the order counted from the bottom of the valence bands. Note that bands mainly composed of Mg2p and Y4p atomic orbitals are omitted from the numbering, although they are explicitly treated as part of the valence bands. Fullsize ImageView full abstractDownload PDF (956K) Full view HTML -

Akihiro Yoshimura, Yasunari MatsunoArticle type: Regular Article

2019 Volume 83 Issue 7 Pages 250-255

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: May 31, 2019JOURNAL FREE ACCESS FULL-TEXT HTMLThe authors have investigated a novel process of platinum recycling using “dry aqua regia”. In our previous paper, it was shown that the recovery of platinum was successfully conducted by the solvent leaching, but obtained as the mixture of K2(PtCl6) and FeOx. In this paper, the solid-liquid separation process using KCl and NaCl solution, and the precipitation process using NH4Cl were adopted to obtain the pure platinum. Impurities like FeCl3, FeOx and KCl were removed through the solid-liquid separation process, and pure (NH4)2(PtCl6) were obtained by the NH4Cl addition. Then, the obtained (NH4)2(PtCl6) was calcinated to obtain pure platinum by the thermal decomposition. The high purity platinum was obtained with the recovery ratio up to 79%. Therefore, usability of the recycling process using “dry aqua regia” was greatly improved.

Fig. 7 Final recovered material, (a) XRD pattern and (b) SEM image. Fullsize ImageView full abstractDownload PDF (2899K) Full view HTML

Fig. 7 Final recovered material, (a) XRD pattern and (b) SEM image. Fullsize ImageView full abstractDownload PDF (2899K) Full view HTML

-

Tadahiko Furuta, Katsuomi Shiina, Yoshihisa Ueda, Shinobu Shimazaki, K ...2019 Volume 83 Issue 7 Pages 256

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

JOURNAL FREE ACCESS

- |<

- <

- 1

- >

- >|